Process transparency and digital intelligence are factors for more sustainability

"The energy data of the material have a massive influence on the overall ecological balance of the manufactured products. Plastics processors expect more transparency and standards here," explains CEO Sandra Füllsack. By means of energy monitoring, it is possible to record the energy consumption of each individual process step. The CO2 footprint of each individual part can be calculated, and the data is certified. This provides the processor with the basis for a systematic optimisation of the energy consumption of his individual production processes.

Process-safe and energy-saving drying

The material drying process is particularly energy intensive. In the latest generation of LUXOR SG small-volume dry air dryers, motan has incorporated the ecoPROTECT function as standard. Depending on the unit size, the function reduces energy consumption by 10%. At the same time, the protective function ensures a secure and reliable drying without over- or under-drying. The mobile small dryers, in which this process-safe technology has been combined with state-of-the-art microprocessor control, are among the trade fair highlights at the motan stand.

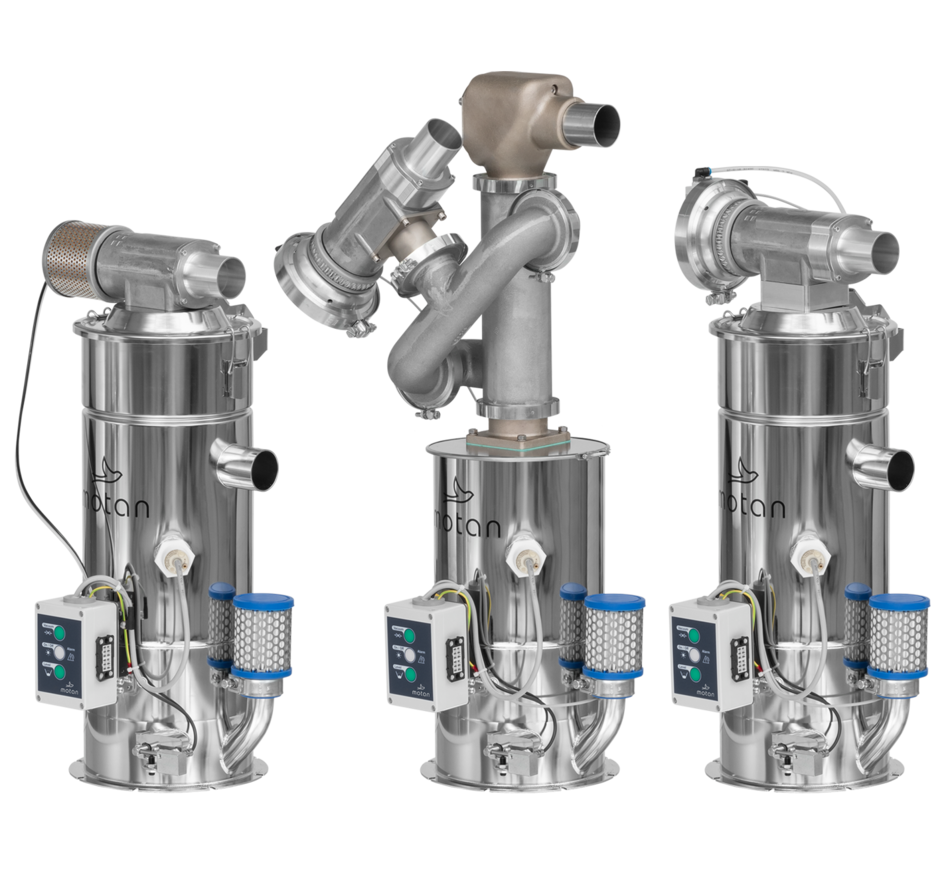

FDA-compliant material conveying and gravimetric dosing and mixing

motan has designed the new METRO G med material loaders especially for plastics processors in the medical and pharmaceutical industries. The extensive family of loaders are based on the established METRO G series of system loaders for plastic granulate and meet all strict hygiene requirements according to FDA 21 CFR. Special attention has been paid to process-safe use in all types of clean room. Special filters with high-quality FDA compliant seals and electropolished stainless steel surfaces ensure reliable, dust- and contamination-free operation. A highlight is the new membrane implosion vacuum valve, which does not require compressed air.

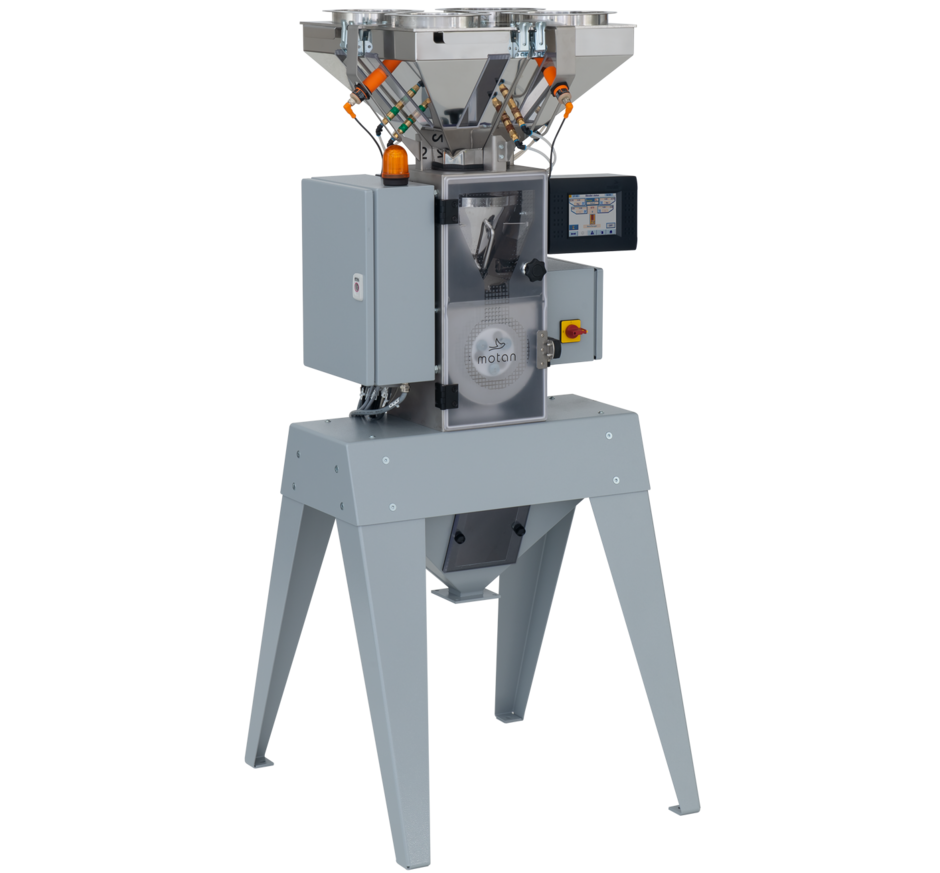

The gravimetric batch dosing and mixing unit GRAVICOLOR 110 med is tailored to the same target group. Like the GRAVICOLOR 110 introduced earlier this year, motan developed this new FDA-compliant version for flexible and reliable mixing and dosing in injection moulding, blow moulding and extrusion applications. Both systems can be seen on the exhibition stand. The dosing and mixing technology is identical. Specially developed vertical slide valves dose and mix up to four different components precisely and with the highest recipe accuracy. The integrated and improved IntelliBlend analysis function records the recipe, material and operating environment and documents all process data. With the help of this function, the user achieves continuous self-optimisation of the system and consequently the best possible operating point with the highest recipe accuracy and consistent, high product quality. Thanks to event-based logging, all parameter changes are stored in a control report and can be subsequently evaluated.

Promoting a holistic understanding of the process

Within the scope of the motan academy, companies can have their personnel trained to such an extent that not only the technology and function of individual units is understood, but also the entire production process. Being able to set up and operate a machine is important. Understanding how settings affect the entire process is even more important. The basic and advanced seminars of the motan academy teach users the interrelationships of material management in theory and practice.

Plastic as a valuable material

In a functioning circular economy with high-quality recycling, material handling plays a key role. To achieve this, motan focuses intensively on the digitalisation of systems and the networking of production processes. The avoidance of material or energy losses through appropriately designed systems is just one aspect that the material management specialist expresses with its slogan 'Zero Loss'. Continuously developing processes and products and making them more sustainable is part of motan's long-standing strategy. Fakuma, Europe's largest plastics trade fair, is an important signal. This is where the motan Group demonstrates how it is helping to shape the future of plastics.